R.beck

Made in Germany – seit 1984

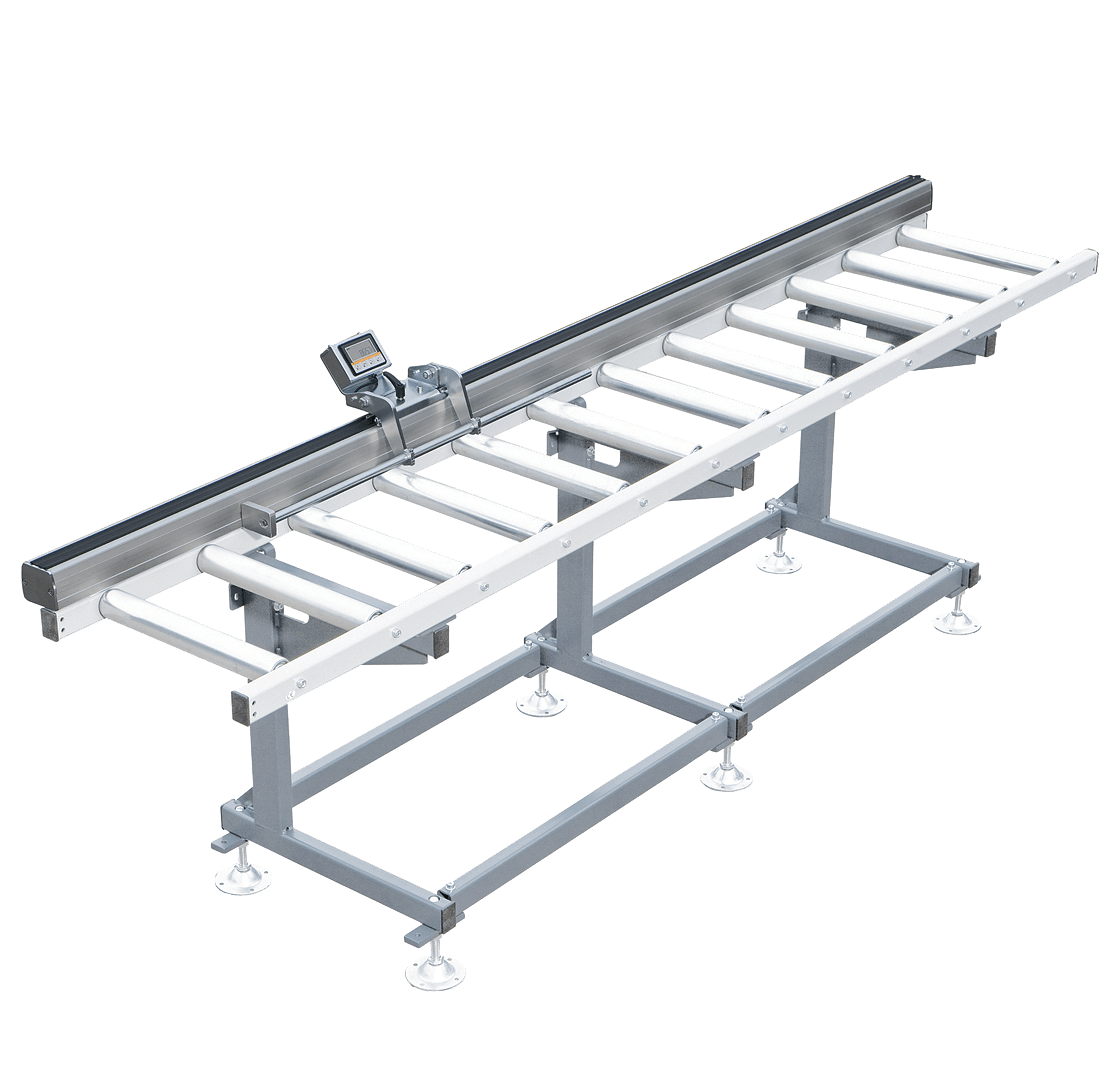

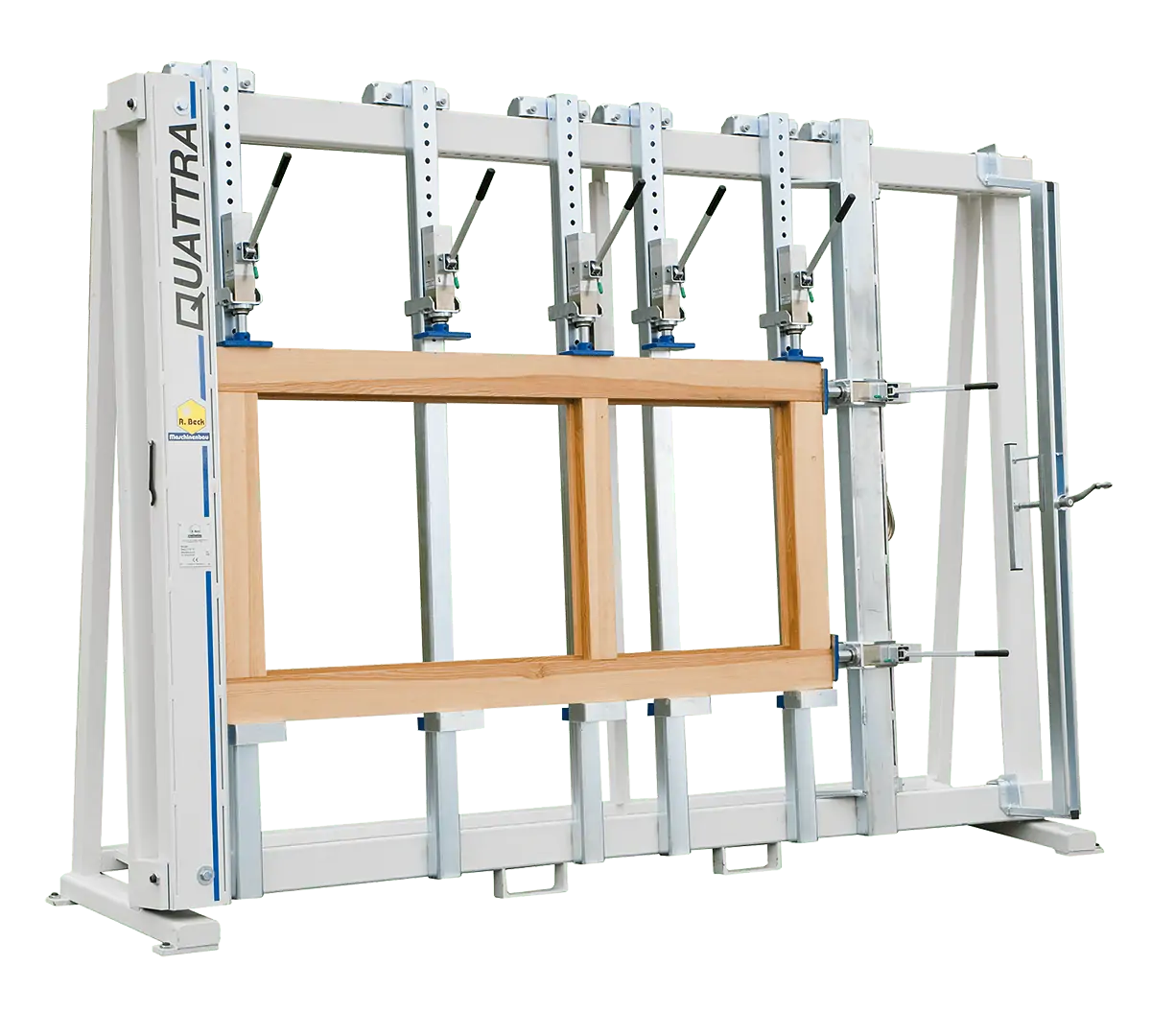

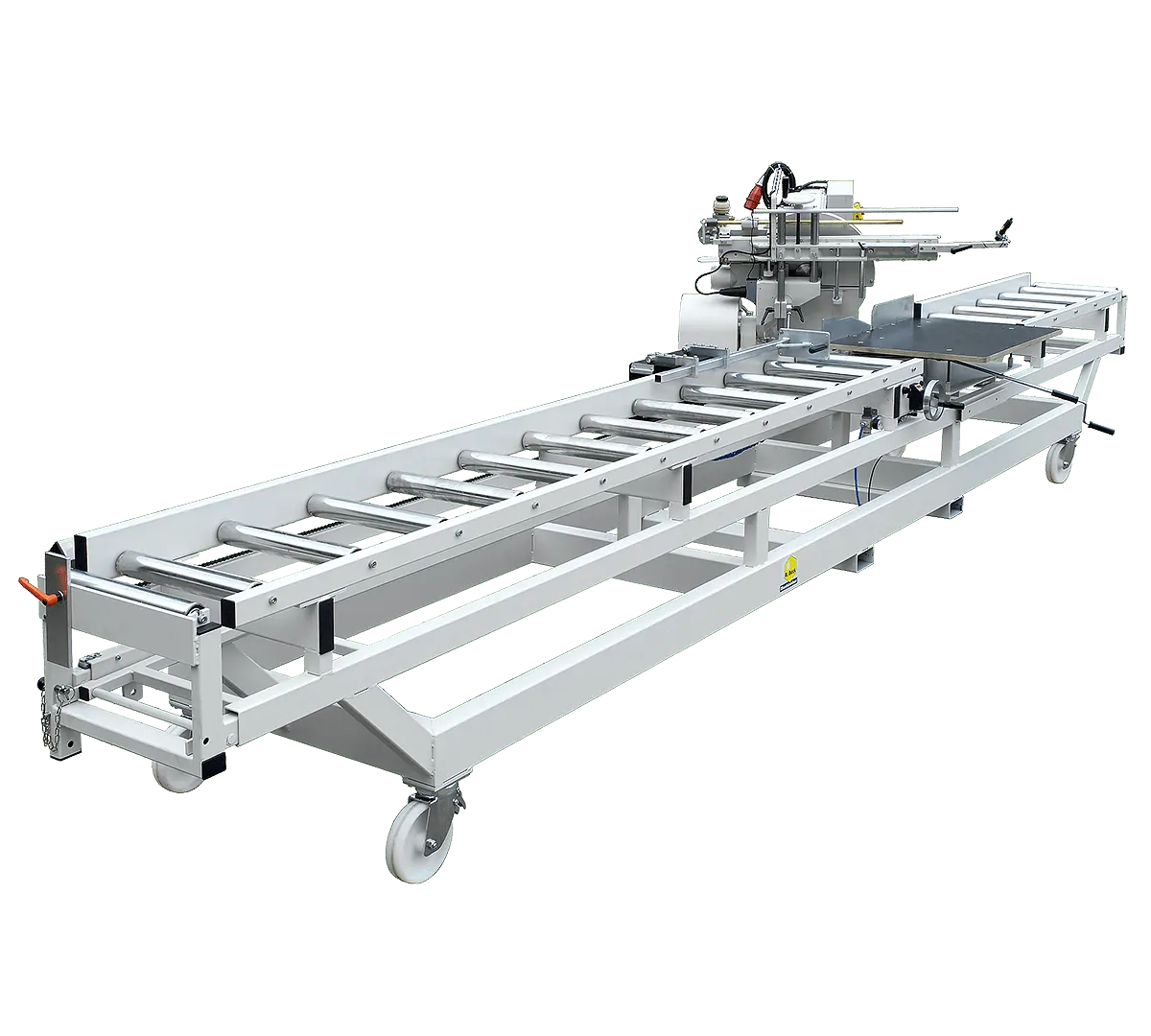

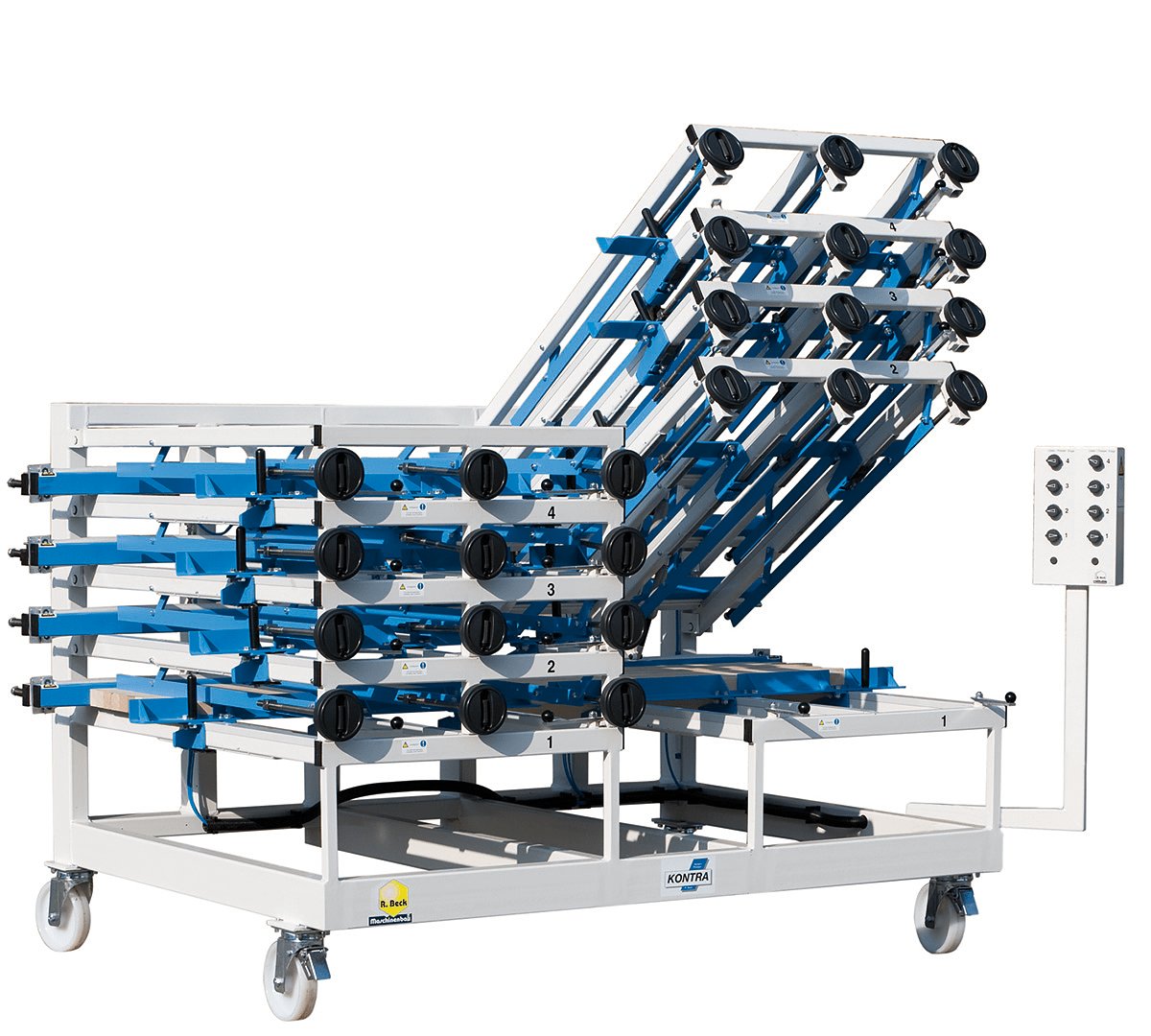

Hub- und Arbeitstische mit jahrzentelanger Erfahrung

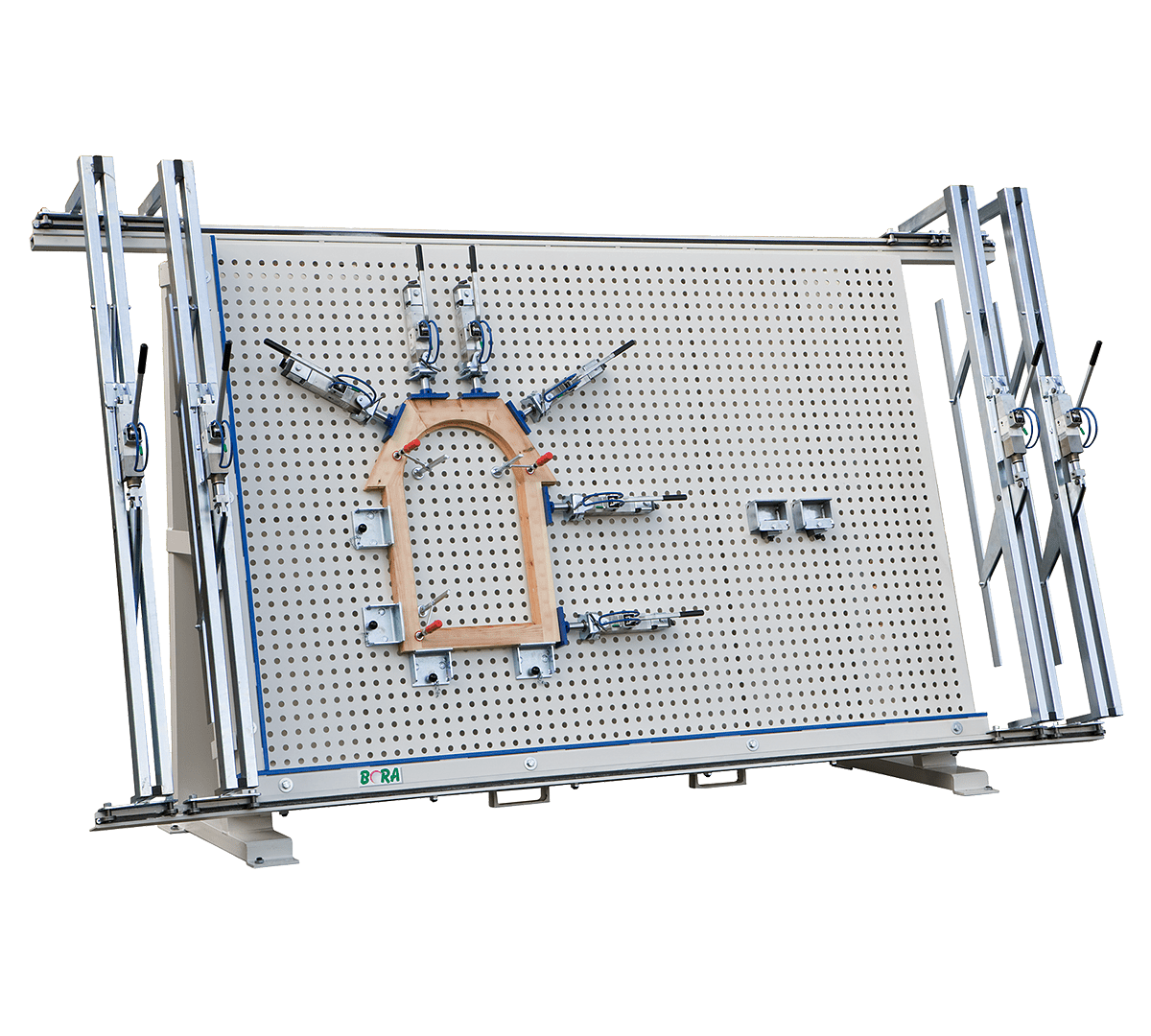

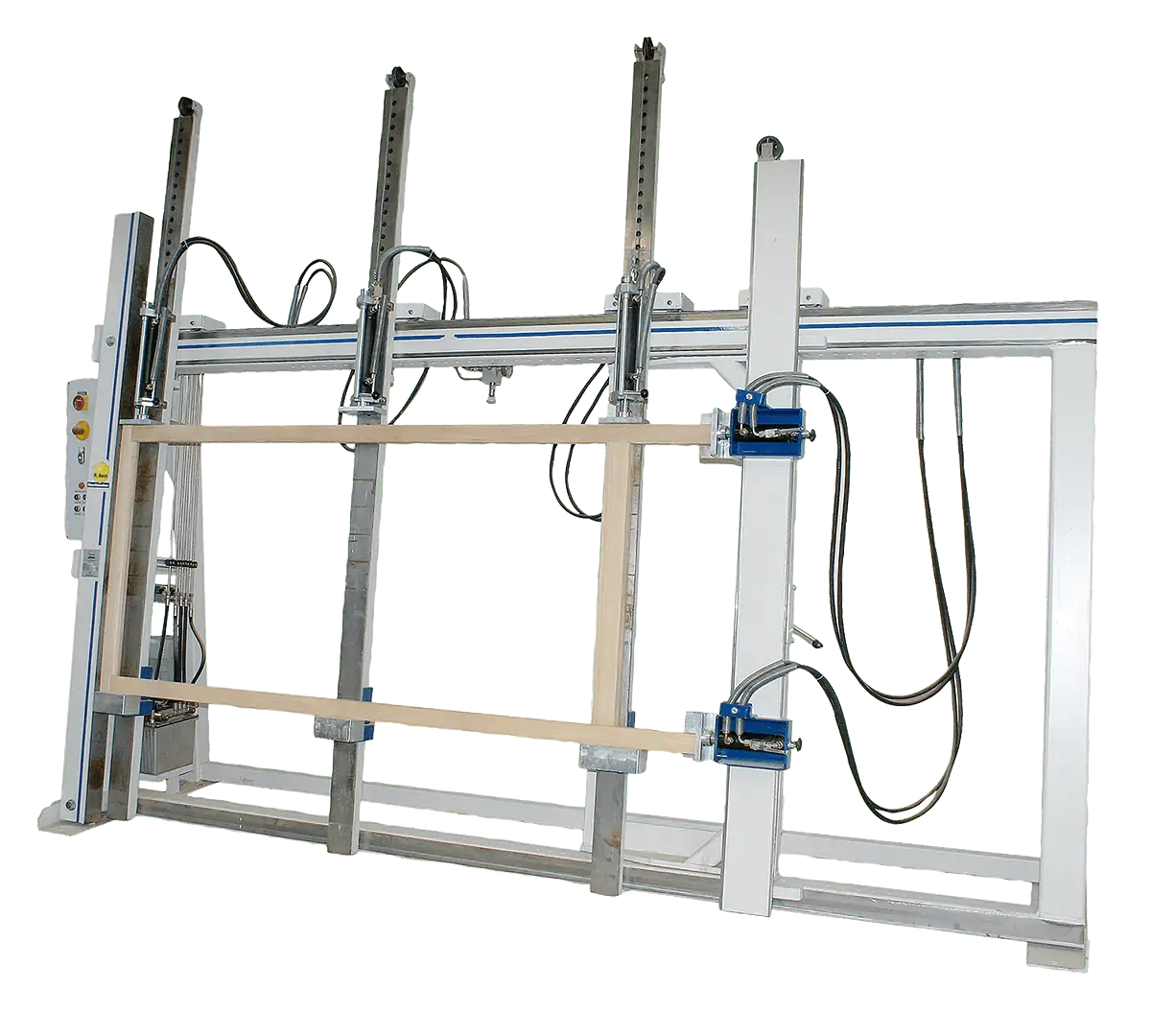

Seit 1984 produzieren wir, die Reinhold Beck Maschinenbau GmbH aus Krauchenwies-Bittelschieß im südlichen Deutschland, für unsere Kunden aus den Bereichen Handwerk und Industrie Arbeitsgeräte, die den Alltag erleichtern und dabei die langfristige Gesundheit nicht außer Acht lassen. Höhenverstellung per Fußhydraulik oder Akku-/Elektrohydraulik sind dabei für uns ebenso unabdingbar wie die Überlegungen, ob ein Arbeitsgerät fahrbar oder stationär eingesetzt wird.

Stets haben wir den individuellen Fall im Blick und ermitteln gemeinsam mit unseren Kunden das ideale, arbeitserleichterne Produkt und greifen bei Bedarf auch dank unserer eigenen Konstruktion und Produktion in Deutschland auf unser Potenzial der Sonderbau-Lösungen zurück. Durch unser langfristiges Know-how und die Erfahrung in vielen Branchen und Betrieben können wir Sie optimal beraten und finden gemeinsam Ihre neuen Arbeitshilfen.

-

HEBEN

-

SENKEN

-

BEFÖRDERN

-

DREHEN

-

KIPPEN

-

SCHWENKEN

Heben

Senken

Befördern

Drehen

Kippen

Schwenken

Messen

Wir sind auf verschiedenen Fachmessen vertreten

Sie möchten uns einmal Live erleben und hautnah die Produkte kennenlernen? Dann schauen Sie doch auf den Messen vorbei, auf denen wir präsent sind. Wir stehen Ihnen dort für Fragen zur Verfügung und zeigen Ihnen gerne, was unsere Produkte so "drauf" haben!

Wir freuen uns auf Ihr Kommen.

Hier finden Sie alle Informationen über die von uns besuchten Messen. Derzeit stehen keine Messen an. Besuchen Sie bald wieder für aktualisierte Informationen.

UNSER NEUER

KATALOG 2024

NEWSLETTER

ABONNIEREN

BECK-PRODUKTE

IM ONLINESHOP